The Cost-Saving Power of VSDs:

How 20% Motor Speed Reduction Can Lead to Significant Savings

Variable Speed Drives (VSDs), also known as Variable Frequency Drives (VFDs), have revolutionized the way motors operate in various industrial and commercial applications. One of the primary advantages of VSDs is their ability to adjust the motor's speed to match the load requirements. In this article, we will explore the potential cost savings when a VSD reduces a motor's speed by just 20%, highlighting the significant impact it can have on energy consumption, maintenance, and overall efficiency.

Energy Savings

The most substantial cost-saving aspect of using a VSD is the reduction in energy consumption. By lowering the motor's speed by 20%, the energy required to power the motor decreases significantly. This reduction occurs because motor power consumption is proportional to the cube of the speed. In other words, a 20% reduction in motor speed results in roughly a 49% reduction in energy consumption. The actual energy savings may vary based on the specific application and load profile, but the principle remains the same - slowing down the motor conserves energy.

For example, if you have a motor that consumes 100 kW at full speed, reducing its speed by 20% would lower the power consumption to approximately 51 kW. This translates to immediate energy savings and a notable decrease in your electricity bill.

Extended Equipment Life / Reduce Maintenance Costs / Improve Process Efficiency

Return on Investment (ROI)

While installing VSDs may require an initial investment, the potential cost savings in terms of reduced energy consumption, extended equipment life, lower maintenance costs, and improved process efficiency can quickly offset this expense. The return on investment for VSDs can often be achieved within a relatively short time, making them a financially prudent choice for many applications.

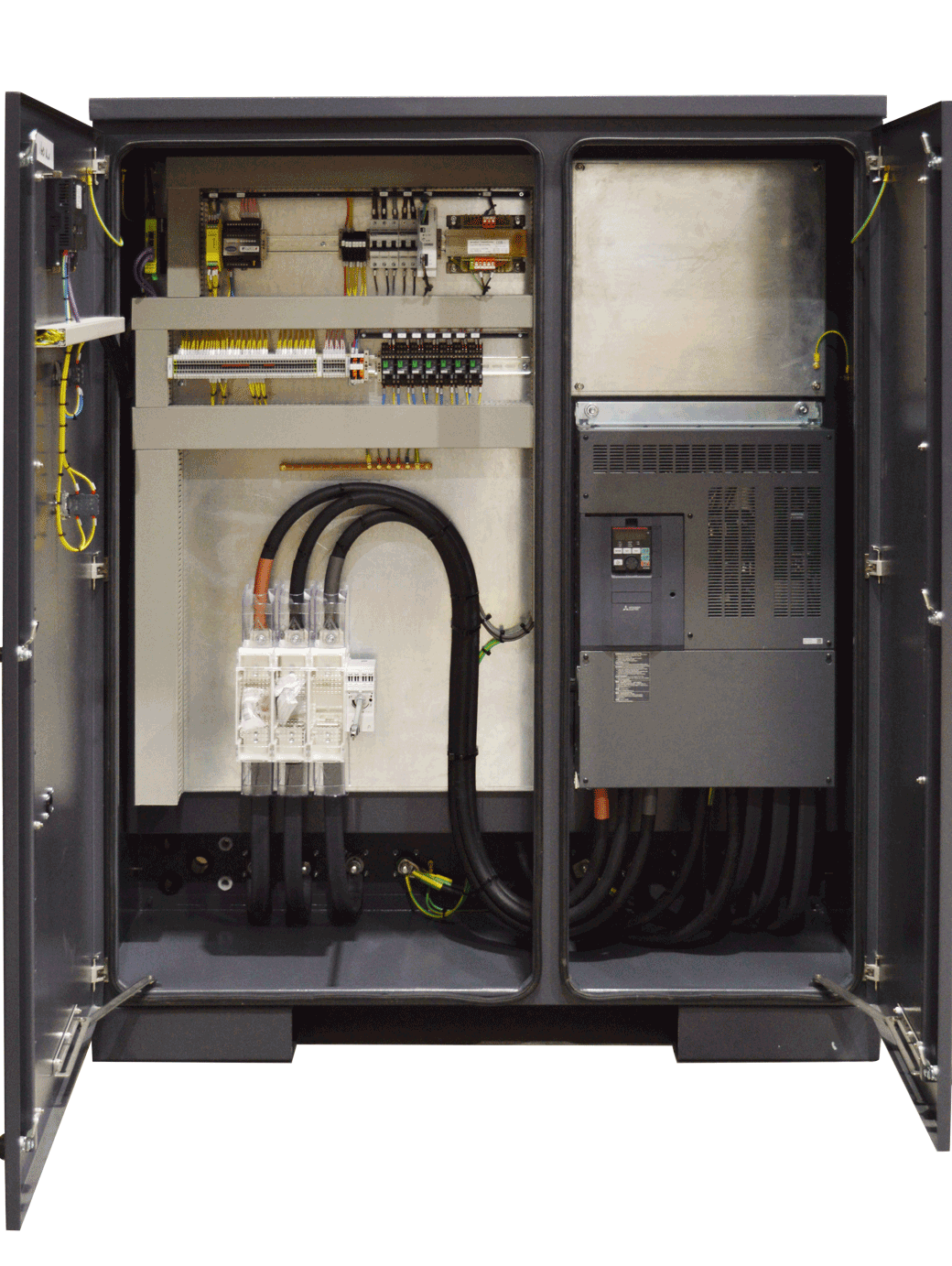

Interior VSD Hire Panel

Extended Equipment Life

Slowing down the motor with a VSD not only reduces energy consumption but also contributes to the longevity of the equipment. When motors run at full speed constantly, they endure more wear and tear, leading to more frequent breakdowns and maintenance requirements. By running the motor at a lower speed, you reduce the stress on the motor, resulting in less wear and tear. This means that the motor and associated equipment are likely to have a longer service life, reducing the costs associated with repairs and replacements.

Reduced Maintenance Costs

A VSD's role in reducing maintenance costs goes beyond extending equipment life. Since VSDs allow for smoother motor startups and shutdowns, they reduce the mechanical and electrical stress placed on the system. This, in turn, lowers the likelihood of unexpected breakdowns and minimizes the need for costly emergency repairs. Planned maintenance activities can also be scheduled more efficiently, leading to lower labour costs and less downtime.

Improved Process Efficiency

VSDs provide precise control over motor speed, enabling the adjustment of the motor's output to match the actual load requirements. This level of control results in improved process efficiency. For instance, in HVAC systems, a 20% reduction in motor speed could lead to more precise temperature and airflow control, which in turn reduces the overall energy consumption while improving comfort and air quality. In industrial settings, processes become more adaptable, allowing for better product quality and reduced waste, which can lead to cost savings.

In conclusion

Incorporating a Variable Speed Drive to lower motor speed by just 20% can result in significant cost savings across various dimensions. Energy consumption reductions, extended equipment life, reduced maintenance costs, improved process efficiency, and a favourable return on investment all make VSDs a powerful tool for achieving economic and environmental sustainability. Therefore, whether you are looking to reduce your energy bills or enhance the efficiency and reliability of your equipment, consider the cost-saving potential of a VSD to optimize your motor's performance.