Sluice Gate gets 25-year life extension

Ensuring Operational Effectiveness for Decades to come!

Design, build and installation of new Control System to operate and manage sluice gates as part of overall refurbishment

Client

NEOM Engineering

Location

Somerset, UK

Service Provided New Control System and Re-cabling

The Challenge

The Sluice is a critical component of flood management in its surrounding Levels and Moors. It regulates the flow of water from a tidal river, a drainage channel built in 1795 and a man made flood relief channel. Constructed between 1969 and 1972, the Sluice plays a pivotal role in safeguarding the nearby historical town and local villages from flooding.

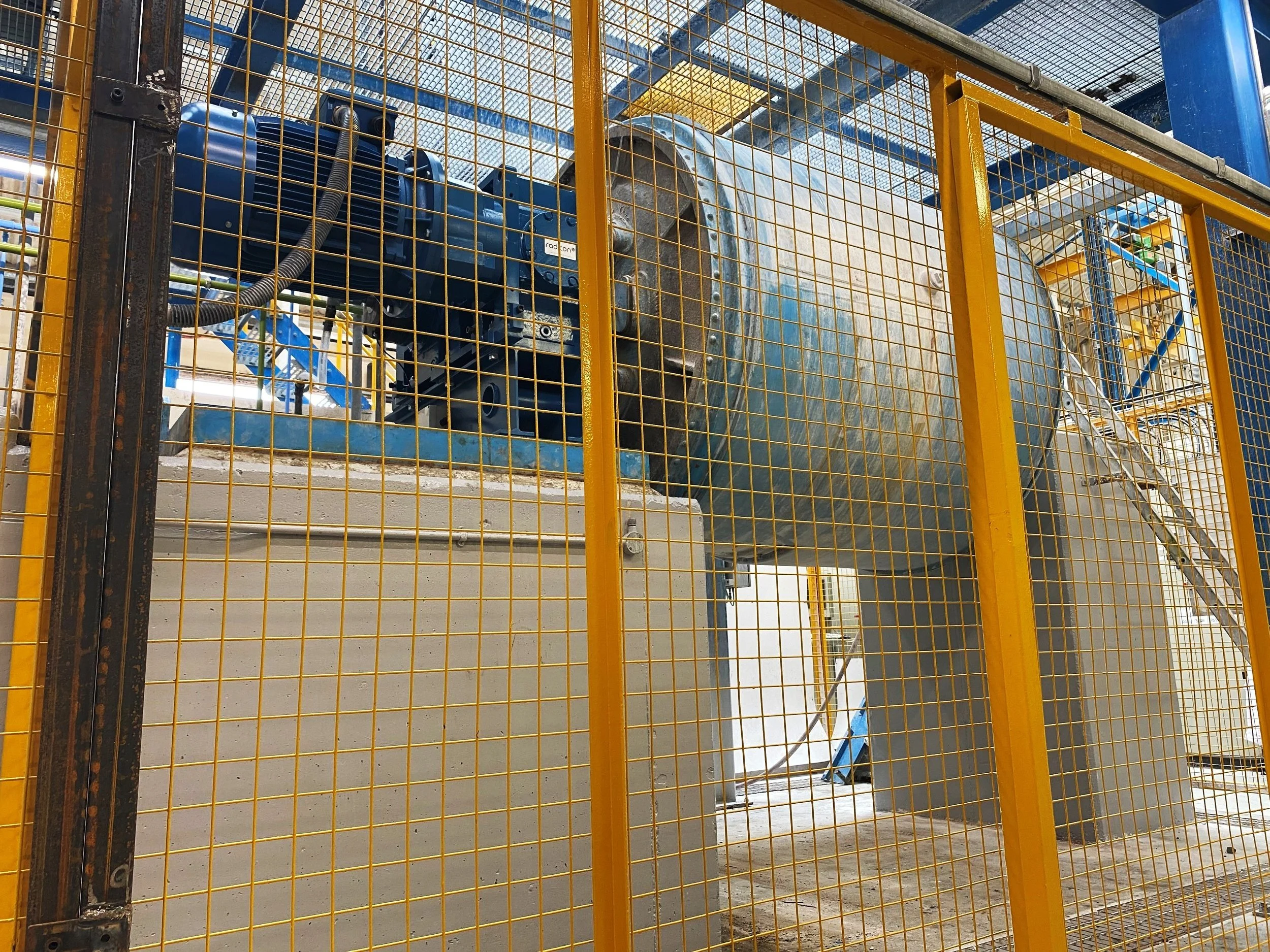

With four main openings, or "eyes," each equipped with two vertical lifting gates and a tidal flap, the Sluice is a complex piece of infrastructure. In 2023-2024, several components underwent refurbishment to extend their operational lifespan. These included the gates, tidal flap valves, and northern bypass channel equipment.

Total Automated Solutions was engaged by NEOM Engineering to design, build and install a new control system and re-cable following the refurbishment.

Water Management

Installation of Schneider M340 PLC and 15” graphical touch screen and Modbus TCP/IP Comms

Design, build and install new Control System and Comms

Before

After

The Options

Two upgrade options were considered, both aimed at ensuring the Sluice's continued effectiveness for the next 25-years.

Option 1: A more basic approach utilising readily available parts. While cost-effective and requiring no computer terminal for fault diagnosis, this option had limitations in terms of future expansion, electrical reliability, and data collection capabilities.

Option 2: A more advanced solution offering enhanced functionality, greater flexibility, and reduced component failure rates. While more costly, this option provided improved safety through integrated interlocks and simplified the implementation of new equipment.

The Solution

Given the need for long-term operational efficiency and robust monitoring capabilities, the customer selected the second option. This solution combined both hard-wired and Programmable Logic Controller (PLC) systems, leveraging advanced automation technologies while ensuring reliable control and monitoring.

The hard-wired system provided a visual representation of the plant's operation, while the PLC system enhanced data collection and offered a digital interface. The Schneider M340 PLC and 15” graphical touch screen improved the ability for data collection and provided a digital interface that replicated the manual control desk’s functions. The integration of the PLC with the client's telemetry system over Modbus TCP/IP comms allowed for a wider range of signals and alarms to be transmitted to the customer’s control room.

New Sluice Gates Automation and Control System Slideshow

Download Case Study

Check-out slides for Total Automated Solutions making of…

The Results

The decision to implement Option 2 resulted in a comprehensive and future-proof solution for the Sluice. By integrating advanced telemetry and PLC systems with traditional hard-wired controls, the upgrade significantly enhanced the Sluice's reliability, flexibility, and operational lifespan.

The enhanced system not only meets current operational needs but is also well-prepared for future challenges, ensuring the continued protection of the regional Levels and Moors. This case demonstrates the importance of investing in advanced automation technologies to safeguard critical infrastructure effectively.

In Conclusion

The successful upgrade of the Sluice has ensured its effective operational functionality for decades to come. In addition to improved gate performance, it reduces the potential for failure and mitigates the risk of flooding to properties. Equally important, it protects freshwater inhabitants and the project has enhanced health and safety for the customer’s staff and contractors.

Our Case Studies