Luxury hotel secures ideal water pressure using Mitsubishi Electric drives and controls

Optimal water management is essential within the hospitality sector, both in terms of delivering a quality customer experience and ensuring hygiene practices are maintained. In effect, a continuous supply of water with consistent pressure contributes to achieving the outstanding service they are looking for to maximise guest satisfaction.

When part of the portable water pumping system of a prestigious hotel in Newcastle required replacing, the facilities management team asked its preferred water specialist, Willow Pumps, to investigate the issue.

As the system featured a complex, highly automated infrastructure, Willow Pumps approached the system integrator Total Automated Solutions. As an appointed Drive Solutions Centre regional centre of excellence recommended using a PLC, variable speed drives (VSDs) and touch screen display from Mitsubishi Electric.

A reliable partner when in hot water

Energy efficient FR-E840 variable speed drives

Neil Heslop, UK Technical Manager at Willow Pumps explains: “Many projects for the water sector are relatively straightforward to implement, but there are exceptions to this rule, which require a more extensive expertise in industrial automation. In these cases, our preferred option is to collaborate with Total Automated Solutions, whose experts have supported us on our most demanding projects, such as the overhaul of this hotel’s water pressure system.”

Following a close inspection of the existing infrastructure, Willow Pumps and Total Automated Solutions were able to recommend a solution that retained some of the existing equipment, but added a PLC control and high efficiency drives to optimise the set-up.

“The portable water pumping infrastructure consisted of two control systems, each responsible for a set of four pumps, which together maintained pressure in the water rising main. We needed to replace the control equipment on one of the pump sets, whilst also integrating the proprietary, vendor-specific drives and controllers on the other set. Based on this requirement, we were asked to re-design the control system, including this would interact with the two pump sets,” adds Rob Iwanuschak, Technical Director at Total Automated Solutions.

MELSEC FX PLC for optimal control

Dependability under pressure

It was essential for the redesigned system to be reliable, offering accurate control, automated duty cycling and energy efficiency whilst also requiring no regular intervention. Coordination between each pump and both pump sets was essential to meet demand swiftly whilst avoiding the simultaneous switching on and off of both sections to prevent any over-or-under pressurisation across the system. All pipework also required regular flow to meet safety hygiene standards.

Hotel control panel when completed

To meet the need for flexibility, reliability, user-friendliness and cost-effectiveness within the application, as well as the hotel’s need to complete the project in a limited timeframe, Total Automated Solutions specified energy efficient FR-E840 variable speed drives (VSDs), a MELSEC FX series PLC and a GOT 2000 HMI to provide real-time monitoring and anomaly detection in the plant room.

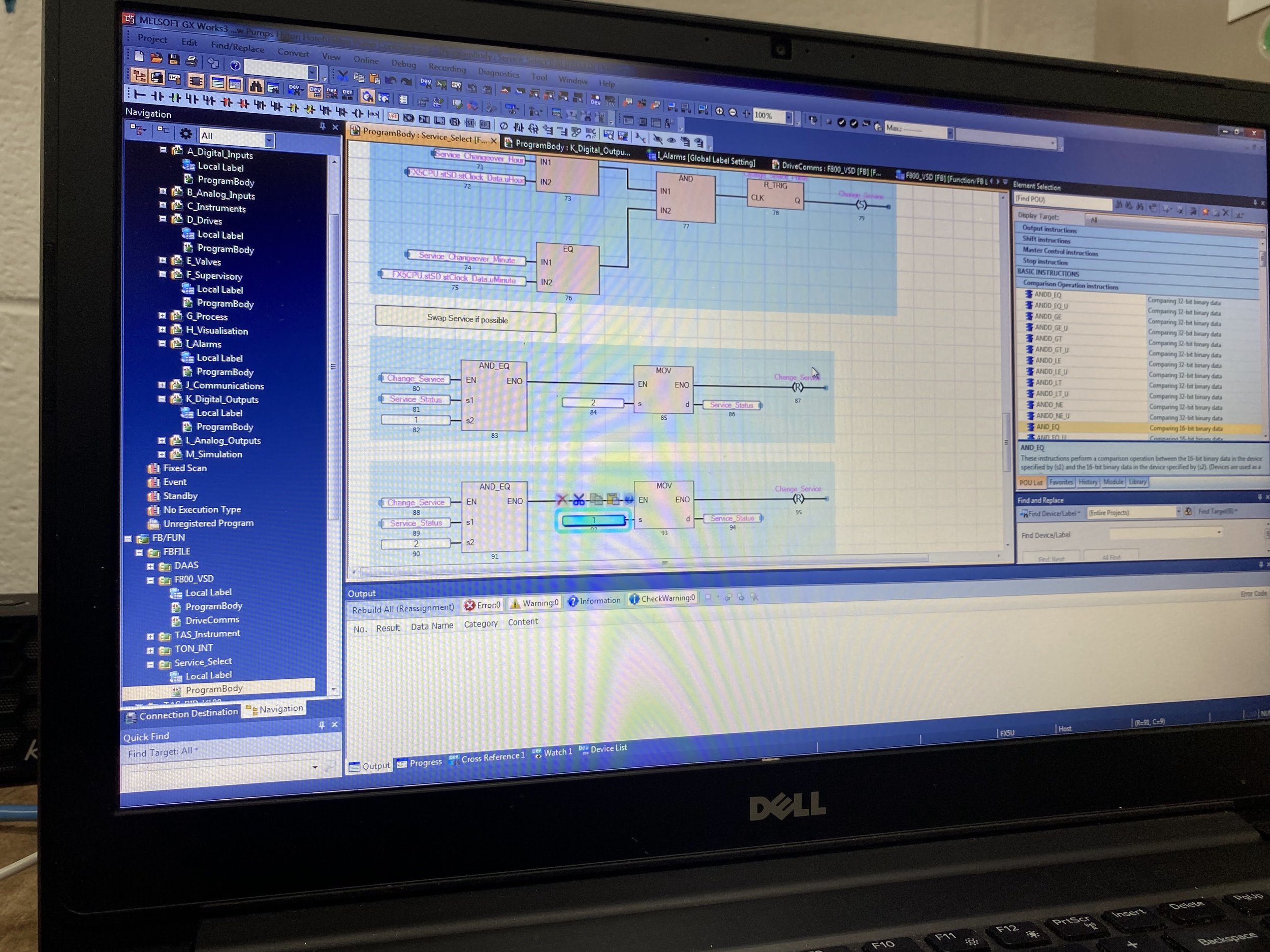

Trevor Herbert, Business Development Manager at Mitsubishi Electric adds, “Integration consideration in a retrofit / upgrade scenario are always important and here the product selection allowed for monitoring and control to be carried out using both an HMI and the existing site monitoring system. The PLC and HMI were configured using our own proprietary Mitsubishi Electric GX Works 3 and GT Designer 3 software, and for speed and security, communication was achieved by using CC-Link IE Industrial Ethernet.

GOT 2000 HMI

Being in full flow

Following the redesign of the system, Willow Pumps and Total Automated Solutions, with the aid of Mitsubishi Electric, were able to complete the installation and testing within four days, without noticeable impact on the hotel’s ongoing water pressure, or availability. In addition to addressing the issues caused by the previous set-up, the new solution offered both improved monitoring and performance. Even more, it now optimises energy management, with considerable savings, as power utilisation is adjusted when the VSDs slow down or accelerate.

Rob Iwanuschak and Trevor Herbert both agree: “We are extremely happy with the automated water pressure system solution, as is the client, and we’re already looking forward to the next challenge”.

Monitoring demand/pressure across the system